Factory Infrastructure

At Fenzy Styles, we integrate cutting-edge technology and a dedicated team with our infrastructure to ensure efficient and flawless clothing manufacturing.

Technology and Expertise

- CAM machinery, automated unit production systems, and computer-aided sewing machinery

- RFID technology for optimized production

- In-house experts in Design, CAD, Industrial Engineering, and Merchandising

Innovative Manufacturing

- Dedicated merchandising team collaborating closely with clients

- Leading the way in innovative manufacturing, combining technology, expertise, infrastructure and customer-centricity

Production Facilities

Latest Machines:

- Overlock machine

- Cover seam flat machine

- Flatlock machine

- Single needle machine

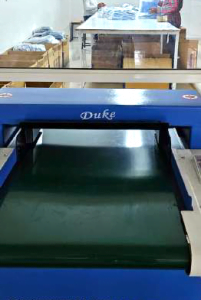

- Heat Seal printing machine

- Needle detector machine

Manufacturing Capacity:

1.25 lakh units per month

Quality Assurance Stations:

- In-House Heat Transfer machines for various sticker applications

- Focus on improving product quality through continuous technological advancements

- Maintenance of Pressing, Spotting, and Packaging Stations

- Orderly workstations for neatness and efficiency

- Consistent inspection of finished products for excellence

Fabrics & Trims

Quality Commitment:

- Thorough inspection of fabric before and after processing, including shrinkage, spirality, and rocking checks

- Meticulous fault marking to streamline cutting room operations

- FPT & GPT tests performed by reputable labs for buyer requirements, ensuring compliance and exceptional quality

Exemplary Fabric Sourcing:

Polyester Knitted:

- Four-way stretch (various compositions)

- Micro PP

- Scuba

- Polar fleece

- NS twill

- NS stretch / NS Plain

- Jacquard

- Embossed Fabric

- AOP Sublimation Print

Cotton Knitted:

- Single Jersey

- Pique

- Interlock

- Blended Fabric

- All kinds of Striper (Auto Str / Feeder Str / Eng Str)

- Jacquard Knit Fabric

- Brushed fleece

- Loop Terry